CORED DC MOTOR

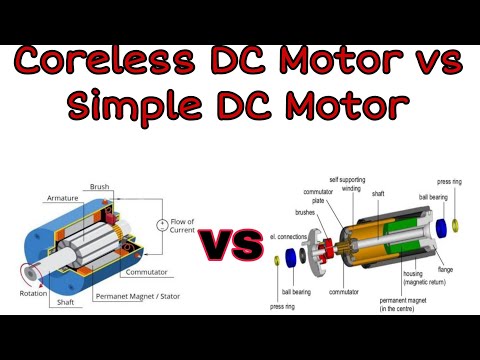

A cored, brushed DC motor is the most popular variety of motor due to its cost effectiveness to manufacture and produce in high volumes. A cored motor consists of a rotor (rotating), stator (stationary), commutator (commonly brushed), and permanent field magnets. Additionally, armature windings are wound around the iron core and connect to the commutator

The brushes, contacting the commutator, are made from graphite/carbon, which allows a connected current to pass through and into the armature windings. The current through the windings produces a magnetic field that interacts with the stationary magnets and generates a force, which rotates the iron core, thereby, turning the motor shaft.

These motors are ideal for demanding applications due to their high starting torque and rigid iron core. They are less likely to overheat thanks to the iron core acting as a heat sink. Large-scale applications include electric cars, lifts, and pumps. Small-scale applications include locomotive sets, electric toothbrushes, and other toys.

Pros

More cost-effective.

High starting torque.

Speed control over a wide range of voltages.

Quick starting, stopping, and reversing.

Free from harmonics.

Cons

Lower electrical efficiencies (approximately 50%).

High maintenance due to wearing brushes.

CORELESS DC MOTOR

What is a coreless motor? It is similar to a cored DC motor in that it has brushes and a commutator. You also get brushless varieties. However, the difference is that the rotors windings are wound in a skewed (or honeycomb) fashion to form a self-supporting hollow cylinder, which is usually epoxied for stability.

The stator, which sits inside the hollow cylinder, is made of a rare earth magnet, such as Neodymium, AlNiCo (aluminium-nickel-cobalt), or SmCo (samarium-cobalt). The brushes in a coreless motor can be made from precious metal (e.g. silver, gold, or platinum) or graphite. The wire cylinder distributes the magnetic field throughout the structure when an electrical current is applied to the leads connected to the brushes and commutator, which interacts with the rare earth magnet to produce a force and rotate the shaft.

Coreless motors open up a wide variety of possibilities for use in robotics. A few applications include their extensive use in prosthetics, insulin pumps, laboratory equipment, and X-ray machines – all requiring high accuracy positioning.

A cored, brushed DC motor is the most popular variety of motor due to its cost effectiveness to manufacture and produce in high volumes. A cored motor consists of a rotor (rotating), stator (stationary), commutator (commonly brushed), and permanent field magnets. Additionally, armature windings are wound around the iron core and connect to the commutator

The brushes, contacting the commutator, are made from graphite/carbon, which allows a connected current to pass through and into the armature windings. The current through the windings produces a magnetic field that interacts with the stationary magnets and generates a force, which rotates the iron core, thereby, turning the motor shaft.

These motors are ideal for demanding applications due to their high starting torque and rigid iron core. They are less likely to overheat thanks to the iron core acting as a heat sink. Large-scale applications include electric cars, lifts, and pumps. Small-scale applications include locomotive sets, electric toothbrushes, and other toys.

Pros

More cost-effective.

High starting torque.

Speed control over a wide range of voltages.

Quick starting, stopping, and reversing.

Free from harmonics.

Cons

Lower electrical efficiencies (approximately 50%).

High maintenance due to wearing brushes.

CORELESS DC MOTOR

What is a coreless motor? It is similar to a cored DC motor in that it has brushes and a commutator. You also get brushless varieties. However, the difference is that the rotors windings are wound in a skewed (or honeycomb) fashion to form a self-supporting hollow cylinder, which is usually epoxied for stability.

The stator, which sits inside the hollow cylinder, is made of a rare earth magnet, such as Neodymium, AlNiCo (aluminium-nickel-cobalt), or SmCo (samarium-cobalt). The brushes in a coreless motor can be made from precious metal (e.g. silver, gold, or platinum) or graphite. The wire cylinder distributes the magnetic field throughout the structure when an electrical current is applied to the leads connected to the brushes and commutator, which interacts with the rare earth magnet to produce a force and rotate the shaft.

Coreless motors open up a wide variety of possibilities for use in robotics. A few applications include their extensive use in prosthetics, insulin pumps, laboratory equipment, and X-ray machines – all requiring high accuracy positioning.

Komentáře